A place for general chat about the Jimny. Please make sure you post in the correct section on the site, this way it keeps the site tidy AND ensures you get a more relevant answer.

Suppliers/Dealers or anyone selling with a commercial view in mind CANNOT post here unless responding to a specific request of a member in a "wanted" post.

Suppliers include people "breaking for spares" on a regular basis, when purchasing spares members should ask a supplier what they contribute to the running of the forum particularly if contacted by a Private Message

Suppliers or Members who have contributed to the forum can be identifed by the logo.

Suppliers/Dealers or anyone selling with a commercial view in mind CANNOT post here unless responding to a specific request of a member in a "wanted" post.

Suppliers include people "breaking for spares" on a regular basis, when purchasing spares members should ask a supplier what they contribute to the running of the forum particularly if contacted by a Private Message

Suppliers or Members who have contributed to the forum can be identifed by the logo.

what welder

- TLW

- New Member

-

Public

Less

More

- Thank you received: 0

16 Dec 2013 00:48 #96314

by TLW

Replied by TLW on topic what welder

Are you limited to a 13amp domestic electricity supply?

One thing to watch is 4mm (without a lot of joint preperation) is thicker than a MIG can easily handle on a 13A supply if you're limited to that. I've a Clarke machine that can handle 2mm (just) but not well or easily (does 0.8mm bodywork very well though).

I've also a Clarke invertor that theoretically needs 16 Amps but will burn a 2mm stick all day, and a 3.2mm stick without to many duty cycle issues and without blowing 13A fuses.

There's always the option to connect a hefty MIG to a cooker socket of course.

One thing to watch is 4mm (without a lot of joint preperation) is thicker than a MIG can easily handle on a 13A supply if you're limited to that. I've a Clarke machine that can handle 2mm (just) but not well or easily (does 0.8mm bodywork very well though).

I've also a Clarke invertor that theoretically needs 16 Amps but will burn a 2mm stick all day, and a 3.2mm stick without to many duty cycle issues and without blowing 13A fuses.

There's always the option to connect a hefty MIG to a cooker socket of course.

Please Log in or Create an account to join the conversation.

- Mister Stu

- New Member

-

Public

Less

More

- Thank you received: 0

16 Dec 2013 06:55 #96327

by Mister Stu

Replied by Mister Stu on topic what welder

In my advise stay away from Clarke stuff.. its cheap and nasty and will only break down, get yourself a MIG machine, anything up to 200amp will run on a 13amp plug and will do up to 6mm on 0.8mm wire

Please Log in or Create an account to join the conversation.

- Mister Stu

- New Member

-

Public

Less

More

- Thank you received: 0

16 Dec 2013 07:24 #96331

by Mister Stu

Replied by Mister Stu on topic what welder

Please Log in or Create an account to join the conversation.

- JerseyJimny

- Topic Author

- New Member

-

Public

Less

More

- Thank you received: 0

16 Dec 2013 07:39 #96332

by JerseyJimny

Replied by JerseyJimny on topic what welder

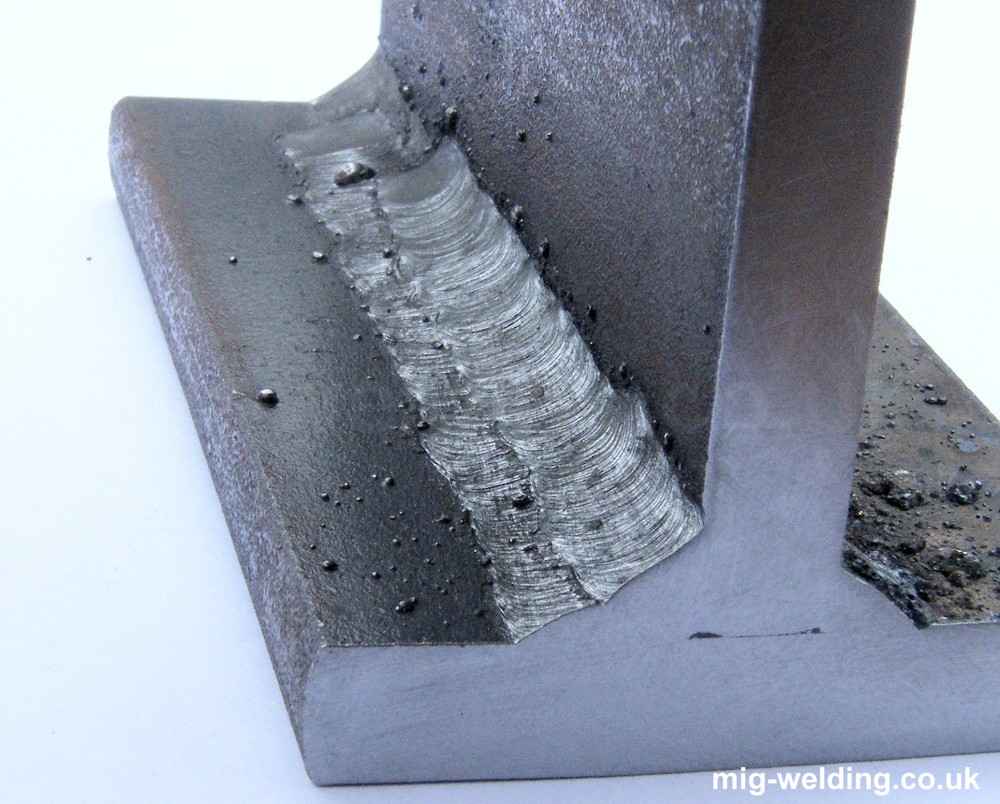

Funny enough it was the best example i could find! :huh:

You would think there would be more pictures of better welds but oh well haha...

Yes there is lack off root pen but the side wall fusion seams to be decent and would hold up to a decent amount of weight

No way of telling until a Macro Etch test was done however

You would think there would be more pictures of better welds but oh well haha...

Yes there is lack off root pen but the side wall fusion seams to be decent and would hold up to a decent amount of weight

No way of telling until a Macro Etch test was done however

Please Log in or Create an account to join the conversation.

- Mister Stu

- New Member

-

Public

Less

More

- Thank you received: 0

16 Dec 2013 08:48 #96339

by Mister Stu

Replied by Mister Stu on topic what welder

This isnt d""k measuring here but iv been in this trade for nearly 12 years and i can tell when i put a run in that il have root and sidewall pen.

Theres and old saying around here that 'if you can piss straight you can mig weld' and its true

Theres and old saying around here that 'if you can piss straight you can mig weld' and its true

Please Log in or Create an account to join the conversation.

- JerseyJimny

- Topic Author

- New Member

-

Public

Less

More

- Thank you received: 0

16 Dec 2013 11:00 #96375

by JerseyJimny

Replied by JerseyJimny on topic what welder

That's the best way to do it

You can weld 6mm plate at around 90 amps with a 2.5 electrode so you have plenty of juice!

Also try your hand at TIG once you get the hang of it you can easily make good looking and strong welds especially on thing stuff

You can weld 6mm plate at around 90 amps with a 2.5 electrode so you have plenty of juice!

Also try your hand at TIG once you get the hang of it you can easily make good looking and strong welds especially on thing stuff

Please Log in or Create an account to join the conversation.

Time to create page: 0.225 seconds